Complete solution for unconventional wells

According to the latest Energy Information Administration data, between 2010 and 2020 the number of horizontal wells in the U.S. increased from 4.4% to 16.9%, and production from unconventional wells in the Permian Basin increased to 75% by 2021, which indicates the high potential of unconventional wells. Despite their great potential, unconventional wells pose a large number of challenges for conventional production methods:

- A rapidly changing well-flow rate; for example, in four months well productivity can drop from 1,749 bopd to 189 bopd;

- High GLR from 600 scf/bbl; and

- High sand content.

At the moment, the main methods of mechanical production for wells with flow rates below 300 bopd are:

- Operation of the ESP unit in Start-Stop mode; and

- Replacement with a sucker-rod pump (SRP) instead of an ESP.

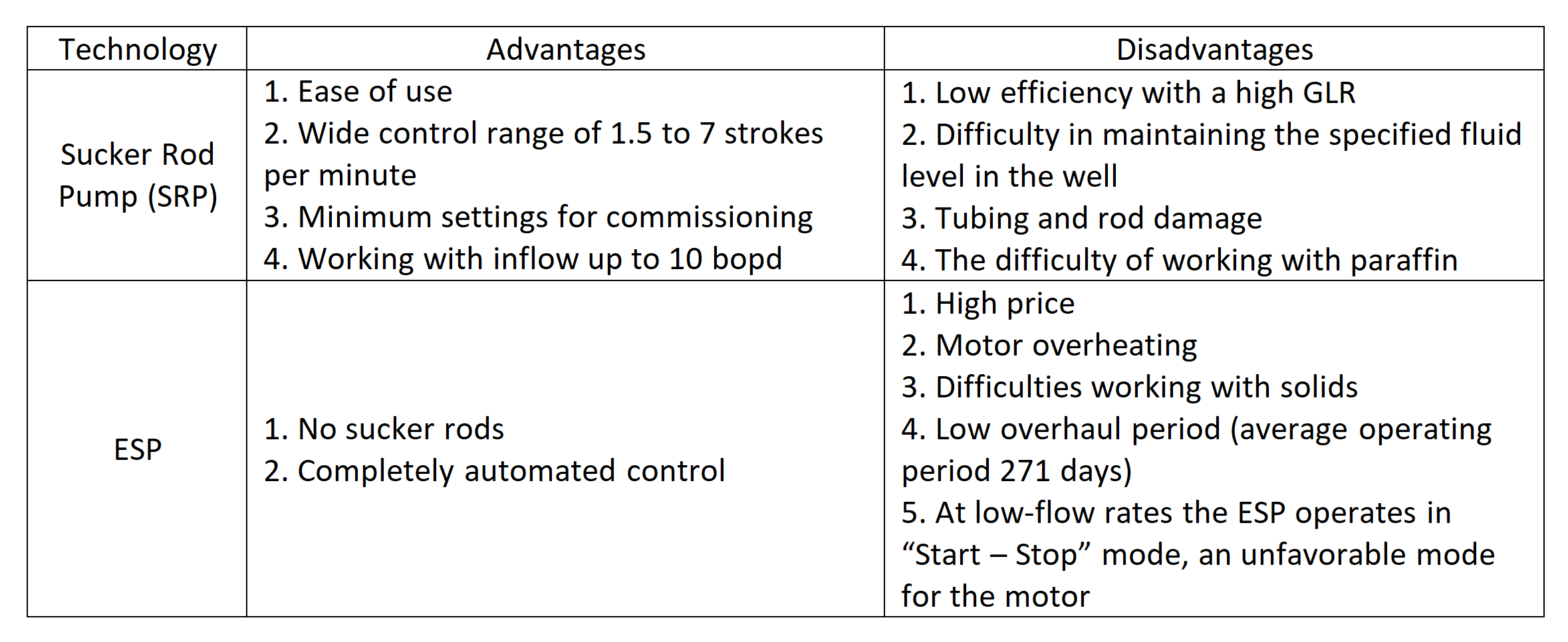

Each of the current technologies has advantages and disadvantages:

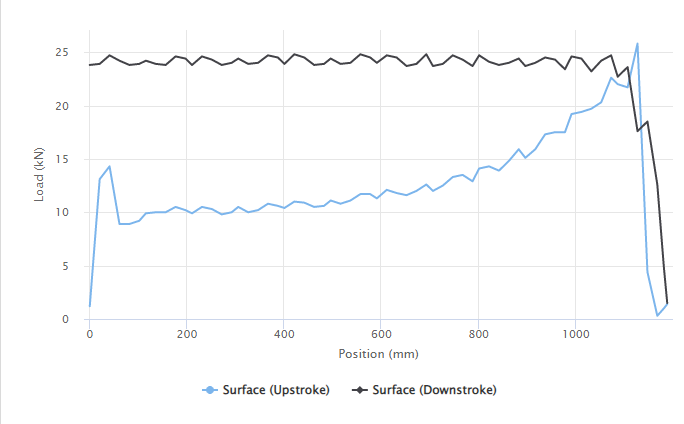

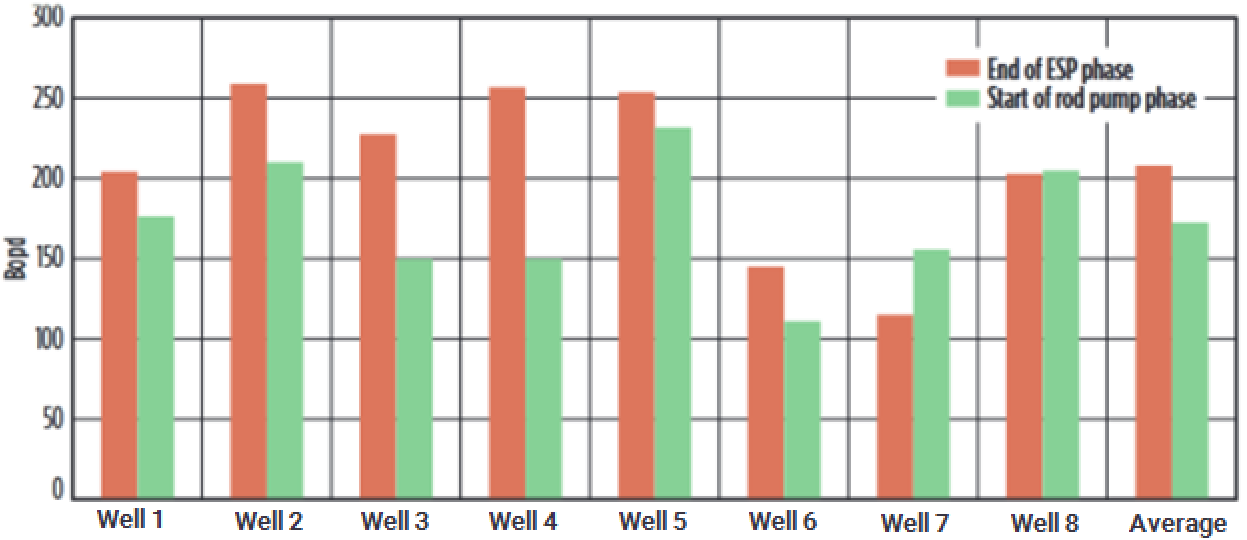

It should also be taken into account that according to the analysis when switching from ESP to the sucker-rod pump, the oil flow rate decreases. The dependence is shown in Figure 1.

Figure 1: Comparison of ESP and SRP flow rates

Triol Corporation offers a unique EP01 solution for unconventional wells with flow rates below 240 bopd.

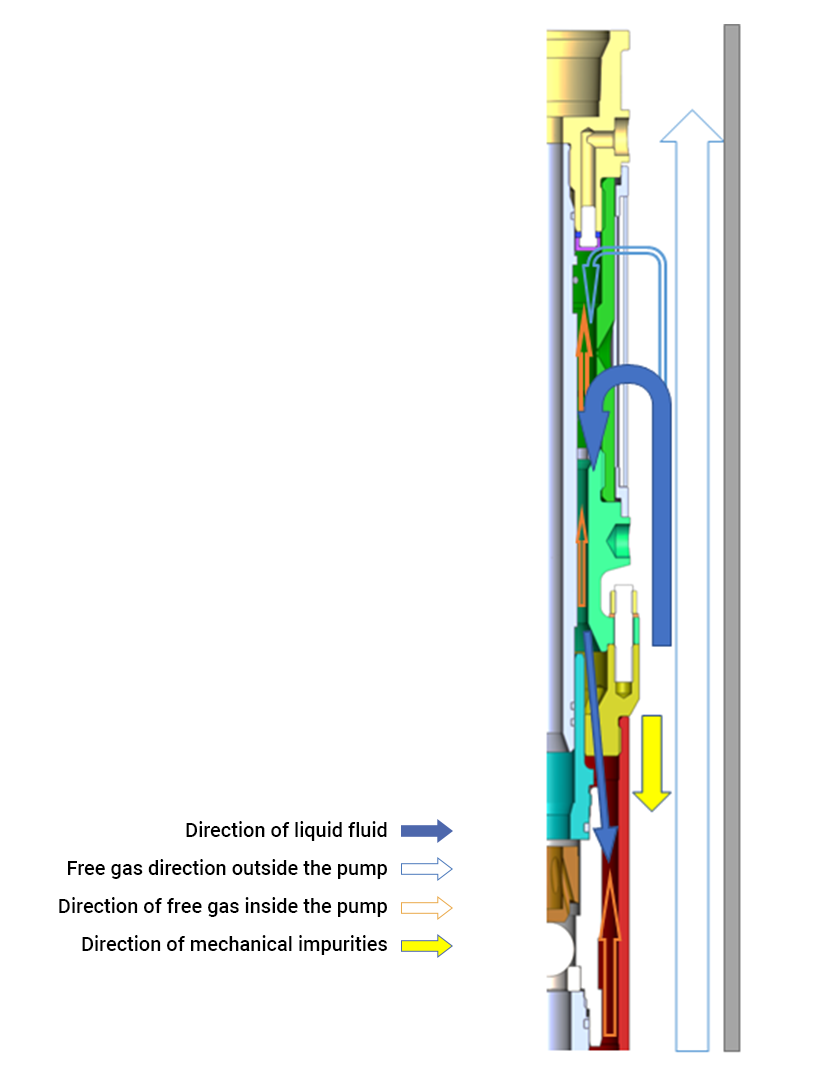

The uniqueness of the EP01 for unconventional wells can be summarized as follows:

1. Continuous operation under minimum flow rate conditions;

2. Operation with a GLR of over 600 scf/bbl; and

3. Working with mechanical particles.

Google

Google

а)

а)